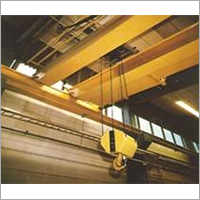

Double Girder Box Type Underslung Crane

Double Girder Box Type Underslung Crane Specification

- Color

- Yellow

- Brake

- Electromagnetic brake

- Gearbox

- Helical type

- Traveling Speed

- 30 m/min

- Electric Hoist

- Yes

- Emergency Stop

- Included

- Application

- Warehouse Material Handling

- Condition

- New

- Load Capacity

- 10 tons

- Max. Lifting Height

- 15 meters

- Max. Lifting Load

- 10 tons

- Span

- 20 meters

- Lifting Mechanism

- Wire Rope Hoist

- Lifting Speed

- 8 m/min

- Operating Mode

- Motorized

- Power Supply

- Three-phase AC

- Voltage

- 415V

About Double Girder Box Type Underslung Crane

Specification

| Brand | Maxx Engineers |

| Usage/Application | Industrial |

| Product Type | Double Girder |

| Power Source | Electric |

| Load Capacity | 5-10 ton |

| Span | 10-20 m |

| Hoist Travelling Speed | 15-20 m/min |

| Finishing | Color Coated |

Efficient Material Handling for Warehouses

This Double Girder Box Type Underslung Crane is engineered to optimize your warehouse operations. With a robust 10-ton capacity and a 20-meter span, it supports the handling of bulky and heavy materials effortlessly. Equipped with motorized operating modes and precise lifting/heavy-duty traveling speeds, your material flow remains uninterrupted and secure.

Advanced Safety and Control Features

Safety is paramount, and this crane includes an electromagnetic brake system, an emergency stop, and reliable wire rope hoist lifting. The inclusion of a helical gearbox enhances operational longevity, while the 415V three-phase AC power ensures consistent performance throughout demanding work cycles.

FAQs of Double Girder Box Type Underslung Crane:

Q: How does the Double Girder Box Type Underslung Crane enhance warehouse material handling?

A: This crane streamlines warehouse operations by providing efficient lifting and movement of loads up to 10 tons. Its motorized controls, rapid lifting (8 m/min), and 20-meter span allow handling of large items across wide spaces, reducing manual effort and expediting workflow.Q: What makes the electromagnetic brake system important for this crane?

A: The electromagnetic brake ensures immediate and secure halting of crane movement, enhancing operational safety by minimizing risks associated with sudden stops or load slippage during lifting or lowering operations.Q: When should I use the emergency stop feature?

A: The emergency stop should be engaged whenever there is an unsafe situation or imminent hazard during crane operation. It instantly halts all crane functions to prevent accidents and equipment damage.Q: Where is this underslung crane most effectively utilized?

A: This crane is ideally suited for warehouses, industrial plants, and manufacturing units where aisle space is constrained and overhead lifting solutions are necessary to maximize floor space and efficiency.Q: What benefits does the helical gearbox offer for crane operation?

A: The helical gearbox provides smoother and quieter gear transitions, increasing the durability and longevity of the crane mechanism while reducing maintenance needs and operational noise.Q: How is the power supplied to this crane?

A: The crane operates on a three-phase AC supply at 415 volts, ensuring robust and consistent electrical energy delivery suitable for industrial-duty cycles.Q: What process is involved in installing and commissioning this crane?

A: Installation involves professional alignment and mounting of the crane, electrical wiring to a three-phase supply, and safety checks on all mechanisms. After setup, comprehensive load testing and operator training are conducted to ensure safe and efficient usage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in EOT Crane Category

Single Girder Box Type Crane

Price 475000 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Emergency Stop : Other, Available

Power Supply : 3 Phase AC

Color : Yellow

Double Girder EOT Crane

Price 200000 INR

Minimum Order Quantity : 1 Unit

Condition : New

Emergency Stop : Yes

Power Supply : 3 Phase

Color : Yellow

Industrial EOT Crane

Price 475000 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Emergency Stop : Yes

Power Supply : Electric / Hydraulic

Single Girder I Beam EOT Crane

Condition : New

Emergency Stop : Other, Available

Power Supply : 3phase AC 50 Hz

Color : Orange

|

MAXX ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry